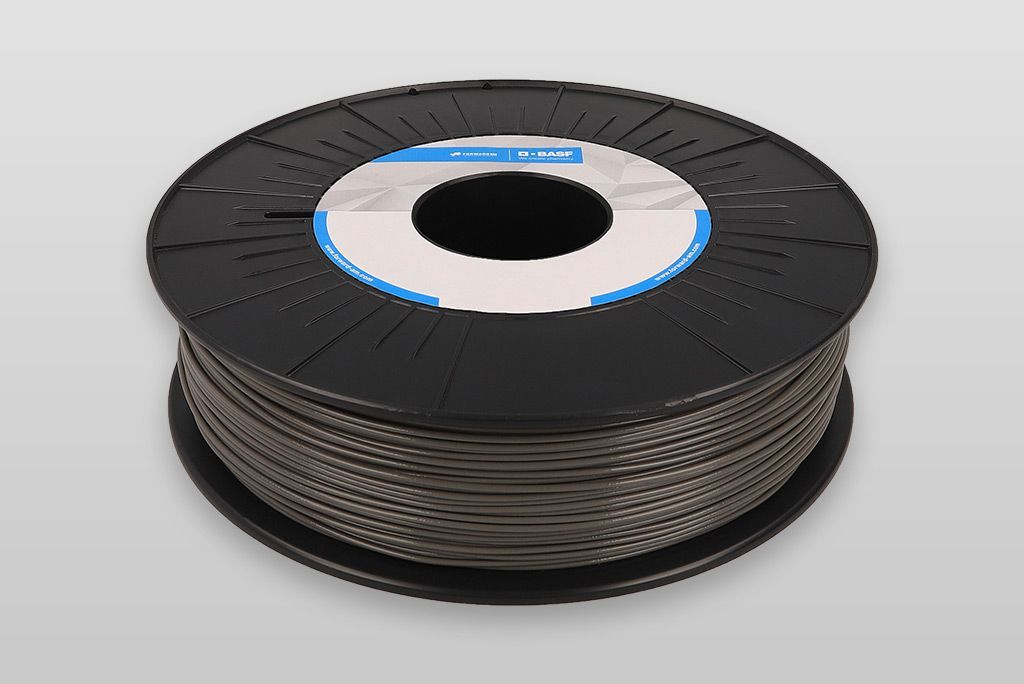

Ultrafuse® 316L

Stainless Steel Composite Metal Filament for 3D Printers

Ultrafuse® 316L is an innovative filament to produce 316L grade stainless steel parts.

Description

It is designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. BASF Ultrafuse® 316L combines greater freedom of design with a lower total cost of ownership – printing metal parts easier, faster and affordable. Parts printed with Ultrafuse® 316L obtain their final properties, including hardness and strength, through the catalytic debinding and sintering process. The catalytic debinding technology was developed and introduced by BASF and has emerged as the industry standard.

Benefits at a Glance

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open source FFF printers

- Produces parts of stainless-steel 316L metal

- Uniform particle distribution enhances mechanical properties

- High flexibility of filament enables successful printing in any FFF printers

- Compatible with both Bowden and direct drive extruders

Example Applications

- Tooling

- Jigs and fixtures

- Functional prototypes

- Small series production

Material Properties

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open source FFF printers

- Produces parts of stainless-steel 316L metal

- Uniform particle distribution enhances mechanical properties